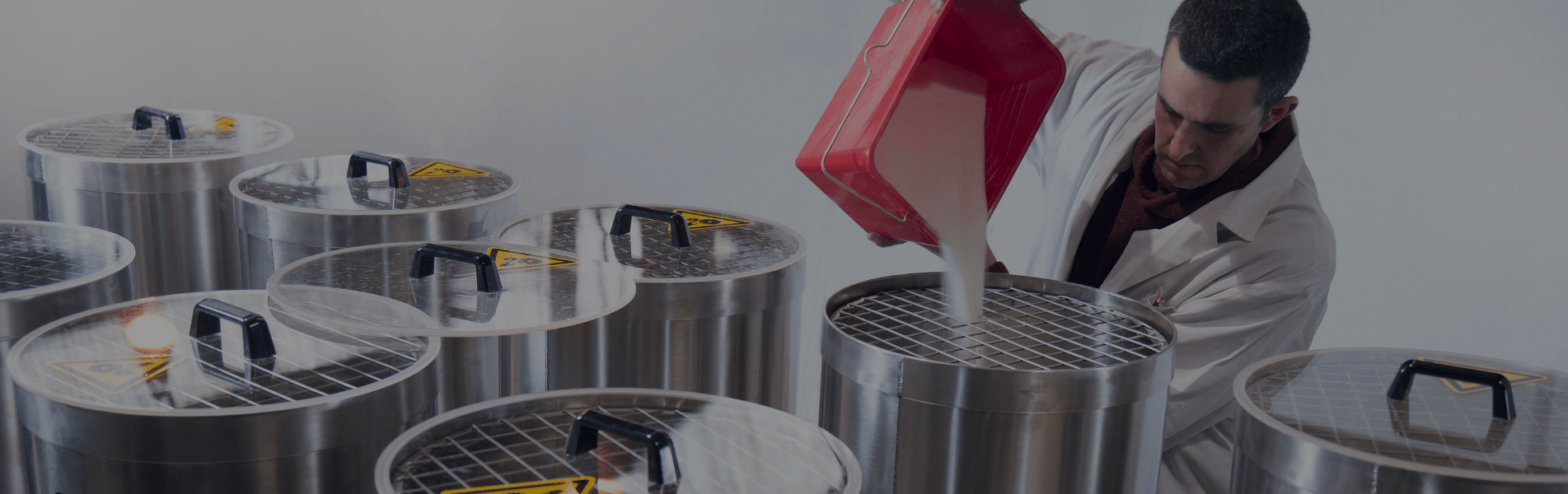

INDUSTRIAL SOLUTIONS FOR THE HANDLING OF SOLID AND LIQUID INGREDIENTS

WE HAVE A PILOT PLANT FOR TESTING AND VALIDATING PROCESSES AS NECESSARY

WE STUDY YOUR PROJECT AND UNDERSTAND YOUR NEEDS TO GIVE YOU A SOLUTION

Why Gashor?

We are leaders in the field of industrial machinery for food.

With more than 60 years’ experience and the guarantee of having worked with more than 3000 customers, we work in more than 15 countries, which makes us the best partner for your industrial food projects, whatever your needs.

Our solutions

We specialise in the storage, transport, dispensing and micro-dispensing of any ingredient in the food sector. We also have a division of industrial food ovens.

Our facilities

Over our more than 60 years of history, we have been fortunate enough to collaborate with leading companies in the food industry. The following are three of our most representative projects.

- Year: 2009, 2010, 2016, 2019

- Solids: Sugar, bran, micros, process

- Horizontal conveyor distance: 40 metres

- Vertical conveyor distance: 10 metres

- • From: Storage silos (90 t)

- To: Mixing buffer hoppers

- Flows: 3000 kg/H

- Type of conveyor: Diluted phase by blowing

- Year: 2011, 2012, 2013, 2014, 2015

- Solids: Flour, bran, reprocessing

- Horizontal conveyor distance: 51 metres

- Vertical conveyor distance: 16 metres

- From: Storage silos (45 t)

- To: Mixing buffer hoppers

- Flows: 3000 kg/H

- Type of conveyor: Diluted phase by blowing

- Year: 2016

- Solids: Taco shell flour

- Horizontal conveyor distance: 45 metres

- Vertical conveyor distance: 4 metres

- From: Storage silos (50 t)

- To: Buffer hoppers

- Flows: 5000 kg/h

- Type of conveyor: Diluted phase by blowing

Contact us

Gashor Customers

"One thing I would like to highlight, which seemed important to me, was all the service we received during the development of the project, including trips, visits and meetings by Gashor. All this allowed us to adapt the entire project to all our requirements."

"We were able to jointly develop a dispensation system for different ingredients at the facilities. The system worked according to our quality standards, increasing productivity, ergonomics and food safety. As a result, we have replicated the system in several production lines."

"Our challenge was to use Tacoshell flour in bulk, avoiding segregation of the raw material in the silos and on the pneumatic conveyor to the mixers. Together with Gashor and our flour supplier, we managed to implement an extraction system and successfully complete the project. It has greatly improved the way we process raw materials."